Intel plans major shift in chip manufacturing: to phase out 18A technology and focus on 14A to boost competitiveness

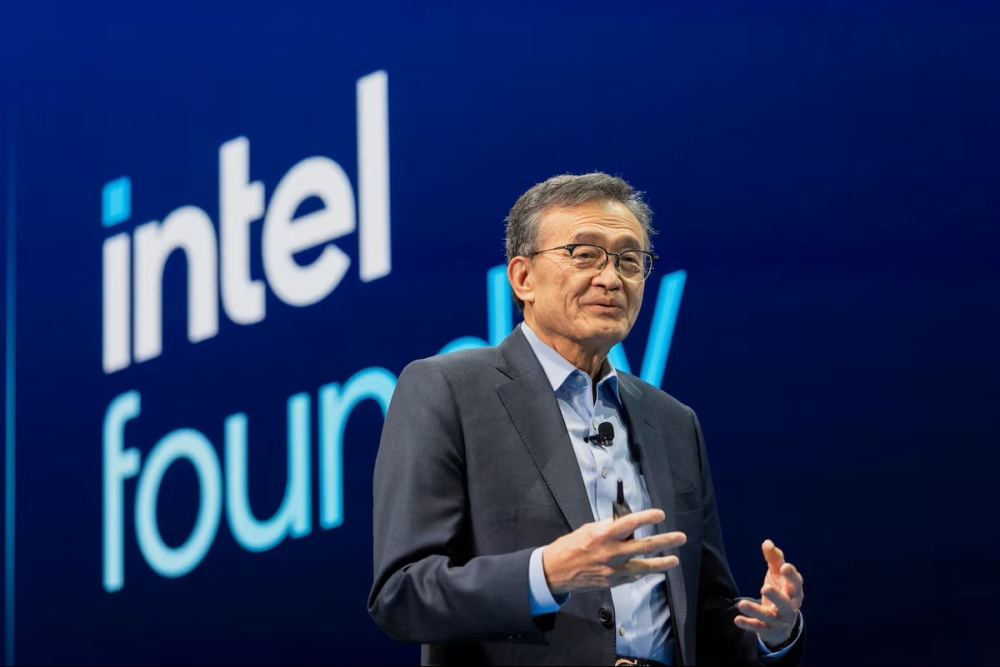

Intel’s new CEO, Lip-Bu Tan, is considering a significant change in the company’s manufacturing strategy to attract key customers to its contract chipmaking division, known as the “foundry.” Tan intends to move away from the “18A” chip production process—a costly technology that previous CEO Pat Gelsinger heavily invested in, with billions spent on its development. If implemented, Intel may take a substantial write-off, potentially amounting to hundreds of millions of dollars.

The new strategy centers on focusing resources on the next-generation “14A” manufacturing process, which is believed to offer advantages over Taiwan’s TSMC technology. Intel aims to attract major clients like Apple and Nvidia with this shift.

Intel’s board is expected to discuss this plan at its July meeting, but due to the complexity and financial implications, a final decision may be postponed until an October meeting.

Currently, Intel itself is the main user of the 18A process and plans to use it for its upcoming “Panther Lake” laptop processors, touted as the most advanced chips designed and manufactured in the United States.

CEO Tan has also been reorganizing Intel’s internal structure to cut costs and improve management efficiency.

By focusing the foundry business on 14A, Intel aims to secure contracts with leading tech companies and regain competitiveness in U.S. chip manufacturing.

This move reflects Intel’s broader goal to restore its lost manufacturing edge and catch up in key areas such as mobile computing and artificial intelligence.

Notably, Intel reported an $18.8 billion loss in 2024, marking its first unprofitable year since 1986.